David Torres’ left arm ends just below his elbow.

Doctors believed it was a lack of nutrients in the womb that led to his arm not forming properly. Torres, who lives near Lawrenceville, has not let this keep him from doing the things he loves. He even wrestled in high school at the state level.

But, a close friendship with a Mercer University student who is president of Mercer Entrepreneurship Engineering Education Program (MEEEP) could extend Torres’ reach with a specially-designed prosthetic arm.

“I think a lot of the time, amputees are viewed as disabled, and I don’t necessarily think of myself as disabled,” Torres said. “The prosthetic is only an enhancement. It’s a tool I’m willing to use, but it’s not what makes me ‘me’ because even with or without a prosthetic, I’m still a fully functional human being.”

Torres, who is originally from El Salvador, said while he never let his arm hold him back, he began to think having a prosthetic would be very beneficial. He said he liked the idea that a prosthetic could assist him in simple tasks and hobbies that are more difficult with only one arm.

“It’s more for my environment, especially people around me who didn’t need to feel uncomfortable. And I need it for comfort too,” Torres said. “It provides a sense of trust that a lot of people like. If you see me doing an activity with one hand, they wouldn’t feel as confident as someone that was doing it with two hands.”

In stepped close friend Mark Boland, a sophomore business major at Mercer and president of MEEEP — a club centered around engineering and entrepreneurial projects.

MEEEP has been involved in various community service programs such as Real Impact, which is an organization that works to increase female involvement in STEM programs in schools. The MEEEP group was also responsible for Macon’s first TED Talk, which took place in 2012.

“We have people from [various majors] (in MEEEP), and we have a bunch of people who were interested in prosthetics,” Boland said. “I feel like it’s not only something really good for my friend David, but it’s also sort of a learning experience for the people in my club.”

Boland got in contact with Dr. Ha Van Vo, a Mercer engineering professor and head of the department’s prosthetics program. Dr. Vo has been working with prosthetics since 2009, and he is in charge of the Mercer on Mission trip to Vietnam, where biomedical engineering majors build prosthetics for people injured by mines left over from the Vietnam War.

Dr. Vo agreed to help create a prosthetic arm for Torres.

“We right now [are capable] for fitting low extremities. Below the knee, above the knee, different type of forceful amputation of that,” Dr. Vo said. “We’re working on the upper extremities and hoping in a few years we’ll have the device for upper extremities like David Torres. But in here, we can help him to do a functional device. But in order to give it to him, we have to get all the material testing, human testing and get approval before we give it to him.”

Torres made the three-hour drive down to Mercer on a Saturday in late November to sign the paperwork and be measured for plans for the prosthetic.

Once he arrived, he and Boland met with Dr. Vo in order to discuss the prosthetic and how Torres might use it.

As the paperwork began, Boland and Torres were taken to the engineering department’s prosthetic lab to create a mold of Torres’ residual limb.

There, they met with Andrew Roy, a graduate biomedical engineering student focused on the field of prosthetics. He began the process of building the prosthetic by creating the mold.

“We take a negative mold, which we later fill with plaster to create a positive mold, which is an exact replica of the patient’s limb,” Roy said. “We do minor modifications, and we create an inner socket which will conform to their limb.”

He said they use a lightweight foam to create the length and the shape of the missing forearm and then laminate it in carbon fiber to give it a sleek appearance that will hide all the internal workings and force structural integrity.

“And then the last thing we do is we decide on a terminal device which is usually bolted onto the end,” Roy said.

The prosthetic will be created based on measurements Roy took when creating the mold. It is expected to be completed sometime in February.

At that time, Torres will then return to Mercer again one final time for the fitting of the finished prosthetic, along with any last adjustments.

Boland is currently pursuing funding for the project from outside sources as well as Mercer’s Bear Grant and special funding programs, which fund clubs and their activities and projects.

Mercer University building prosthetic for Lawrenceville man

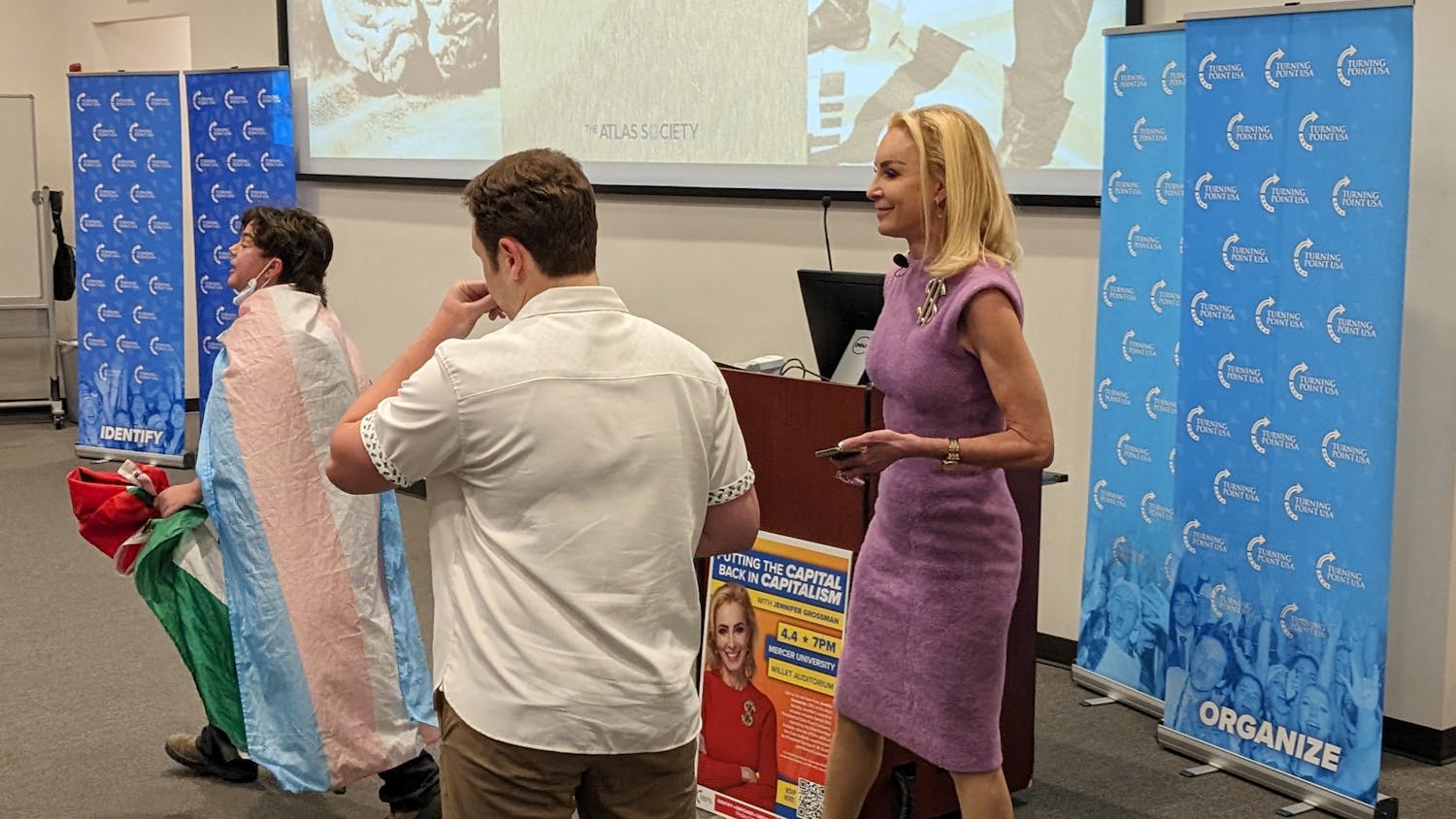

Andrew Roy takes measurements of David Torres’ arm to fit for the prosthetic.